Die Casting is a process were molten metals like aluminum, zinc or magnesium are forced with high pressure into a die cavity. During this process large amounts of oil mist and oil smoke consisting of sticky particles is formed from the release agent and the piston cooling oil.

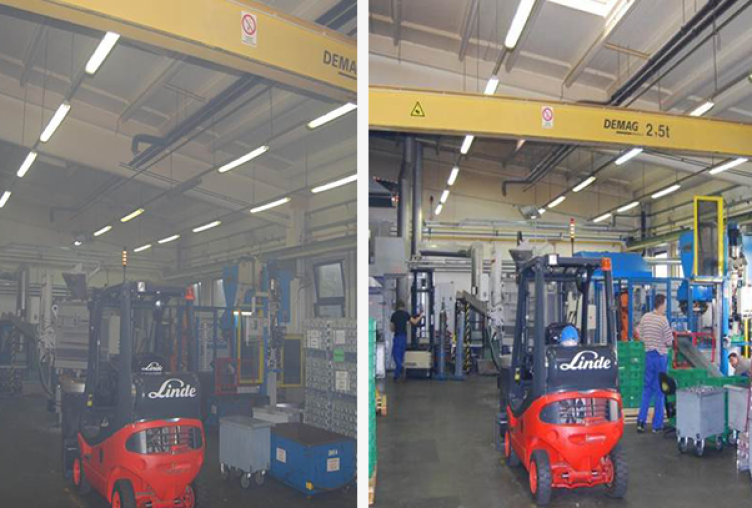

The first challenge is to capture the mist/smoke-filled cloud that is pouring out of the die-casting machine. A properly designed hood and a capable filter solution is the main condition to create a good work environment.

One source of oil smoke is the lubrication that is being sprayed into the mold cavity. It is often called release agent and contains various mineral oils, graphite, petroleum and natural waxes etc. Another source of oil smoke is the injection of the molten metal which takes place through the shot sleeve (piston lubrication). Together these sources create a task too tough for most filter units to handle. It is not unusual that a medium size die casting machine releases more than 1000 kg of sticky, dirty particles into the air every year. Just imagine what all this dirty air is doing to your company and to your employees. Absolent’s vast experience in designing hoods that capture the air effectively also minimizes the size of the filter unit. If heat is needed elsewhere in your facility, you can use the extracted air. Energy smart and health safe – just the way we like it!

Companies within die casting that have chosen Absolent

Filters perfectly suited for die casting

Do you want to know more?

Want to get in contact with us? Please leave your information here and we will get back to you as soon as possible.

We look forward to hearing from you!